Potassium Monopersulfate (KMPS)

CAS : 70693-62-8

Potassium Monopersulfate (KMPS)

DESCRIPTION

Potassium Monopersulfate compound is a white, granular, free flowing peroxygen that provides powerful non-chlorine oxidation for a wide variety of industrial and consumer uses.

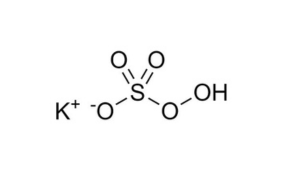

The active ingredient of KMPS is potassium peroxymonosulfate, KHSO5 (CAS 10058-23-8), commonly known as potassium monopersulfate, which is present as a component of a triple salt with the formula 2KHSO5·KHSO4·K2SO4 potassium hydrogen peroxymonosulfate sulfate (5:3:2:2), [CAS 70693-62-8]).

Structural Formula: 2 KHSO5 * KHSO4 * K2SO4

KMPS undergoes a strongly acid reaction in aqueous solution. As a result of its high oxidation potential and microbiological effectiveness, it can be used for many different applications. It has the particular advantage of being highly stable in storage, easy and safe to handle, free from chlorine and of having a high reactivity.

PROPERTIES

| Test Items | Specifications |

| Appearance | White Powder or Granule |

| Available Oxygen (%) | >4.50 |

| Loss on Drying (g/L) | <0.1 |

| Bulk Density (g/L) | >800 |

| pH Test (10g/L, 25oC) pH | 2.0-2.3 |

| Particle size (0.850~0.075), % | >90.0 |

APPLICATION

· Denture cleaner: Effective main ingredient in cleaning tablets for dentures.

· Disinfectant: Use for chlorine-free disinfection or purification of swimming pool water and spas. Prevention of chlorine acne and eye irritation. Approved for oxidative drinking water treatment.

· Bleaching agent: KMPS has a bleaching effect comparable to that of organic peracids; in the TAED/perborate system it is particularly effective at low temperatures.

· Biocidal effect: Suitable as an additive to acidic cleaning agents with bleaching and disinfectant effect.

· Effluent treatment: Oxidative treatment of problematic effluents; sulfide oxidation, nitrite oxidation and cyanide detoxification.

· Plaster additive: Addition of KMPS leads to generation of oxygen and improved product characteristics (e.g., thermal insulation, water absorbency, mechanical properties).

· Metal treatment: Microetchant: Use for etching printed circuit boards.

· Others:

- Textile finishing (shrink proofing of wool)

- Chemical synthesis (production of dioxirane)

- Paper manufacture (repulping, particularly of wet-strength paper).

STORAGE

KMPS must be stored under dry conditions. It must be protected from direct sunlight and from any other sources of heat.

Standard Packing of KMPS is 25 Kg bags

Enquiry Now